- For secure high-pressure

- +36 62 999 051

- info@pwent.eu

Termékek

- Home

- Termékek

- Products

- Gas cylinder pressure testing and refurbishment machines

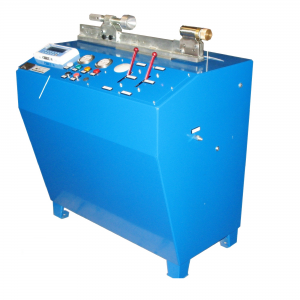

- FIT100 model- Semi automatic hydraulic testing unit

FIT100 model- Semi automatic hydraulic testing unit

Mainly extinguishing systems, gas cylinders of periodic pressure used for testing .

Semi final automatic, Gas cylinder spaces: 1 Gas bottle diameter 200-410/500/610 mm, Gas cylinder length: 250-1850 mm, Maximum test pressure: 100 bar.The unit is designed to execute testing of all cylinders that require periodic review, in particular for liquefied gas cylinders that are used into firefighting installation. The testing takes place in semi-automatic mode: the unit will automatically manage the three phases of testing (filling, pressurization, water drain). Unit needs authorization of the operator to switch from one phase to the sequent.The FIT100 is composed by: an inverter, designed to clamp the cylinder safely and manage the rotation upside-down of 180°. A process unit containing all the elements necessary for the management of the three phases of testing.A water storage tank A safety perimeter for protection of cylinder tilting area.

Complete solution for gas cylinder pressure testing in the following variation.

Variations

- FIT100-1 (MZCZ008-AA) pressure testing machine for gas cylinders with max 420 mm diameter

- FIT100-1 (MZCZ008-BB) pressure testing machine for gas cylinders with max 5000 mm diameter

- FIT100-1 (MZCZ008-CC) pressure testing machine for gas cylinders with max 610 mm diameter

Download

| Weight | 650 kg |

|---|---|

| Gázpalack helyek | 1 |

| Maximális próbanyomás | 100 bar |

Related products

- Ajánlatkérés

99/D1 transfer pump

2 250,00 €99/D1 unit is mainly suitable for fire-fighting and industrial gas applications and for any other employment requiring to transfer liquid CO2 from standard cylinders to containers or to fire extinguishers with more than 1 kg capacity.

- Select options This product has multiple variants. The options may be chosen on the product page

99/D3 SODA series CO2 filling and transfer unit equipment

9 200,00 € – 9 600,00 €Price range: 9 200,00 € through 9 600,00 €A töltőgép alkalmas cseppfolyós széndioxid gázpalackból történő átfejtéshez töltéshez.

- Ajánlatkérés

N7/15 model Electrically driven high pressure test pump

N7/15 is equipped with a 3 piston electrically driven test pump able to perform hydraulic test up to 500 bar depending on the version

- Ajánlatkérés

N7/1FH-E-portable electric testing pump for extinguishers

1 860,00 €The pump is easily transportable as it is installed on a trolley equipped with a special three-wheeled structure.