- For secure high-pressure

- +36 62 999 051

- info@pwent.eu

Gas cylinder stamping, marking

Showing 1–12 of 16 results

- Ajánlatkérés

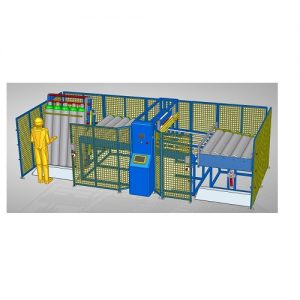

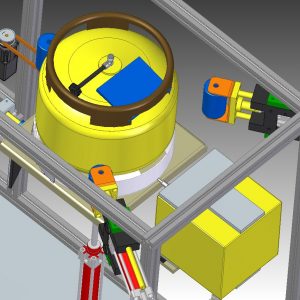

SPSN1492 Gas cylinder marking machine for production line

High volume, automatic Gas cylinder marking for production line. High-power, precision dot-marking.Automatic loading and unloading

- Ajánlatkérés

Industrial engraving marking stamping – unique machine design and production

Unique marking, engraving, stamping machine design and production for your need. Suit to you product.

- Ajánlatkérés

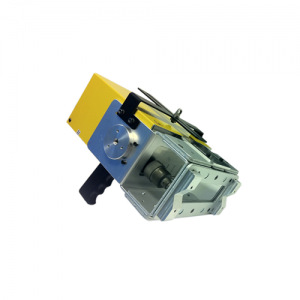

MK3-X80 gas cylinder stamping machine

9 420,00 €Gascylinder marking, High-power, precision dot-marking. Marking window 80 x 50 mm. Head with aluminium adapter for gas cylinders. Metal security schutters and additional air suctions holes provide the clean air and the spare parts cleaniness

- Ajánlatkérés

S series all in one benchtop marking device

5 460,00 €ALL-IN-ONE BENCHTOP MARKING DEVICE with touchscreen. Marking window 130 x 100 mm. With column, with touch screen control.

- Ajánlatkérés

MK3-M80-IP65 stamping machine for integration for wet conditions

IP65 protected high-power, precision dot-marking for integration. Marking window 80 x 50 mm. Metal security schutters and additional air suctions holes provide the clean air and the spare parts cleaniness. Includes control unit, cables, but not includes stylus and touch screen.

- Ajánlatkérés

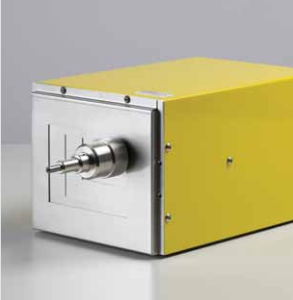

MK3-M80 stamping machine for integration

High-power, precision dot-marking for integration. Marking window 80 x 50 mm. Metal security schutters and additional air suctions holes provide the clean air and the spare parts cleaniness. Includes control unit, cables, but not includes stylus and touch screen.

- Ajánlatkérés

TES-M8-3 marking head without programming unit and gas cylinder adapter

3 340,00 €Marking head WITHOUT programming unit and gas cylinder adapter

- Ajánlatkérés

2320-ASM-001 aluminium adapter for MK3-X80

Cylinder marking fixture in aluminium for gascylinder marking

- Ajánlatkérés

- Ajánlatkérés

MK3-TCS-7-1 additional desktop touch screen

Optional Desktop touch-screen 7″ color display for online for configuration, programming, job execution and variable data input.

- Ajánlatkérés

SCH-TCS-7 spare touch screen

Spare Touch-screen panel with interface board

- Ajánlatkérés

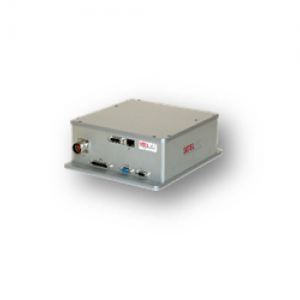

BOX-ELT complete control box WITHOUT touch screen

Complete control unit without touchscreen

Gas cylinder stamping and marking is a vital process in the management and safety of gas cylinders. This involves applying specific markings and stamps to gas cylinders, providing vital information about their contents, specifications, and safety instructions. It’s imperative that these markings are accurate, clear, and legible, as any unreadable or obscured information can lead to the discarding of the cylinder due to safety concerns.

Standards and Challenges in Gas Cylinder Marking

The international standard for gas cylinder stamping and marking, primarily guided by ISO 13769:2018, mandates a uniform stamp marking system for identifying cylinder contents and conveying safety information. The International Organization for Standardization (ISO) and other regulatory bodies play a critical role in setting these standards, which ensure global safety and efficiency in handling gas cylinders. Adherence to these standards ensures consistent and reliable practices for safe usage.

Legibility of these markings is non-negotiable. Issues such as thick paint covering insufficiently deep indentations or manually made markings being inconsistent and variable in depth are significant concerns. Hand-made marks can lead to inconsistencies, with some parts of the text being more visible than others. In contrast, machine inputting of these markings ensures consistent quality, making it easier and more reliable for anyone to read.

Additionally, these markings often include ownership details, such as the company name and contact information. This not only facilitates easy identification but also guarantees ownership, adding another layer of security and traceability to the management of gas cylinders. The precision and clarity of these markings are paramount, as they are integral to the safe and efficient use of gas cylinders in various industries.

Standards for Gas Cylinder Marking

The international standard for gas cylinder stamping and marking is primarily guided by ISO 13769:2018. This standard outlines the stamp marking system for identifying cylinder contents and providing safety information about the gas contained within. Organizations like the International Organization for Standardization (ISO) play a crucial role in setting standards that contribute to the global safety and efficiency of gas cylinders. Their guidelines help in maintaining consistent and reliable practices for the safe handling and usage of these containers worldwide. As dictated by these standards, a uniform system for cylinder marking facilitates easy identification and understanding of cylinder contents and related safety measures.

Components of Gas Cylinder Markings

Several key components form the part of gas cylinder stamping and marking:

- Cylinder Specification: This indicates the type and capacity of the cylinder.

- Serial Number: A unique identifier for each cylinder.

- Date of Manufacture: The date when the cylinder was manufactured.

- Neck Ring Identification: Markings on the neck ring for additional cylinder identification.

- Retest Markings: Dates and details of periodic cylinder testing for safety.

- Cylinder Manufacturer’s Inspection Marking: Indicates the cylinder has passed manufacturer inspections.

- Cylinder Tare (Empty) Weight: The weight of the cylinder when empty. This is particularly important for cylinders containing liquefied gases, as these gases are typically charged by weight.

Each of these components is crucial for the comprehensive identification and management of gas cylinders. They provide necessary information for users, inspectors, and regulatory bodies, ensuring that the cylinders are used and maintained correctly.

Importance of Compliance

Compliance with gas cylinder stamping and marking standards is not just a regulatory requirement, but also a key factor in maintaining the safety and proper use of gas cylinders. This adherence is vital for preventing accidents and promoting these containers’ correct and safe utilization. Accurate and legible markings help prevent accidents and misuse by providing essential information at a glance.

Technological Advancements

Advancements in technology have enhanced the gas cylinder stamping and marking process. Techniques such as dot-peen marking, rollmarking, laser etching and permanent marking are now used to ensure that markings remain legible throughout the cylinder’s life, even in harsh environments.

Rely on Pwent for precise and compliant gas cylinder stamping and marking, ensuring safety and clarity in every detail.