- For secure high-pressure

- +36 62 999 051

- info@pwent.eu

Products

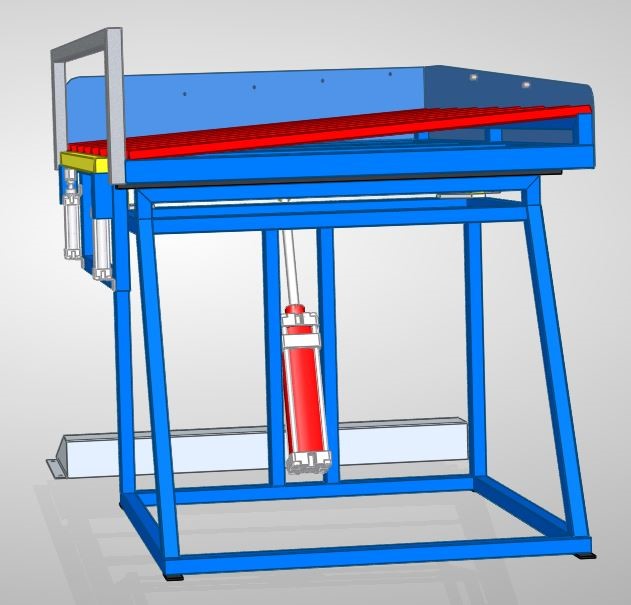

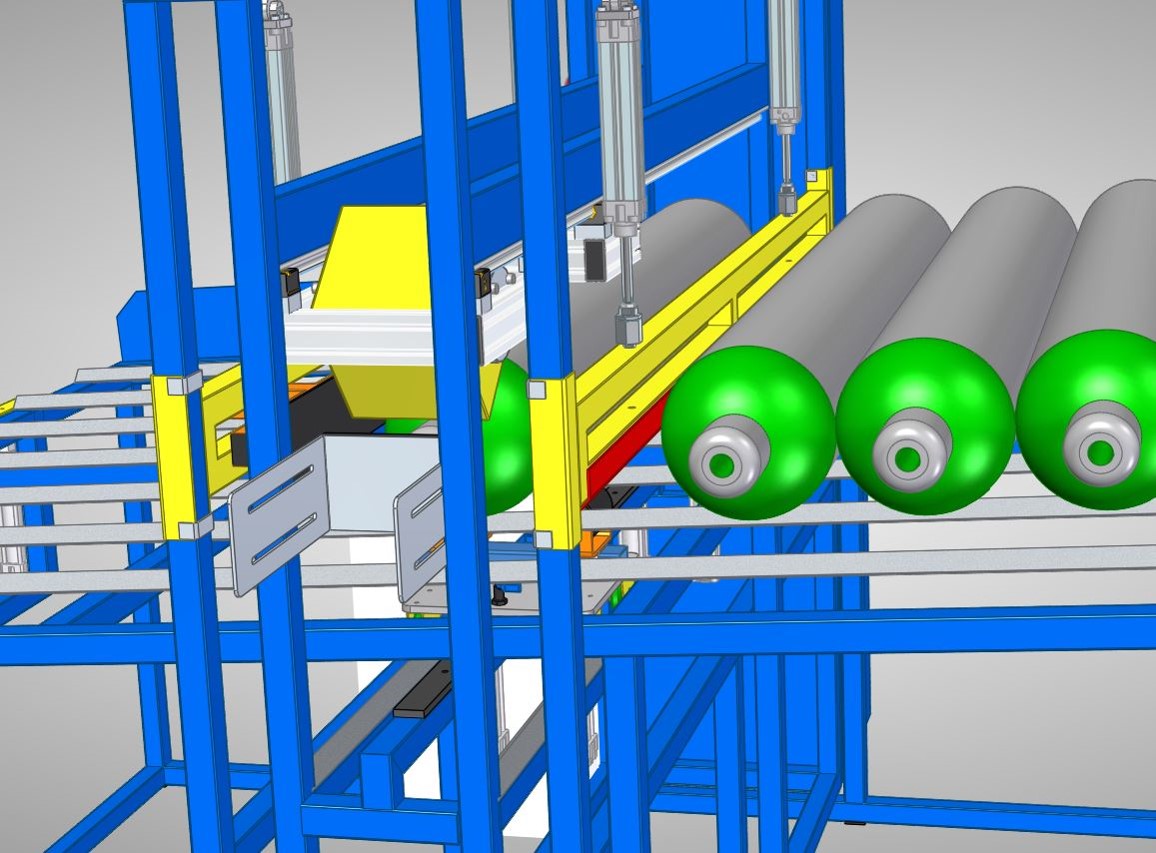

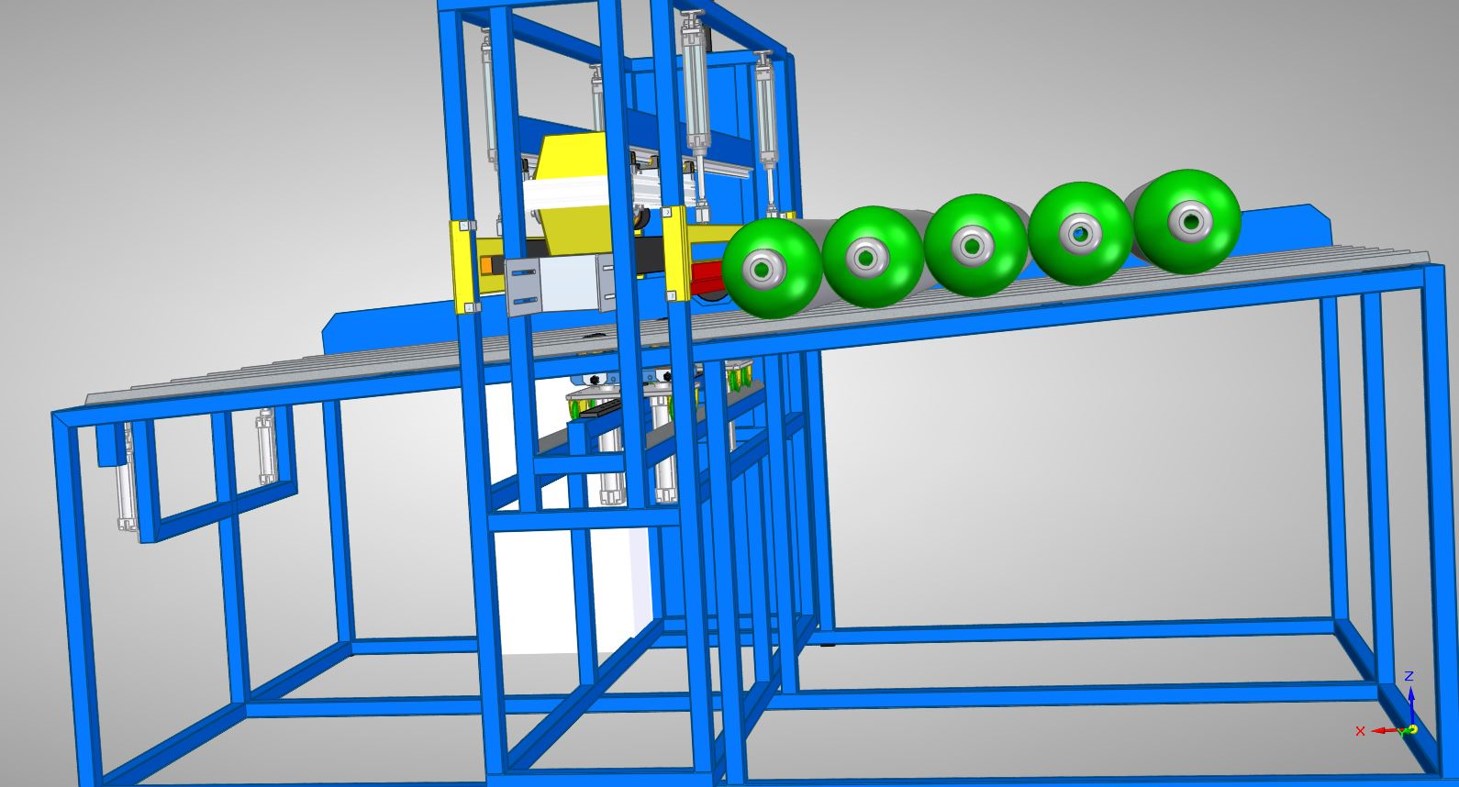

SPSN1492 Gas cylinder marking machine for production line

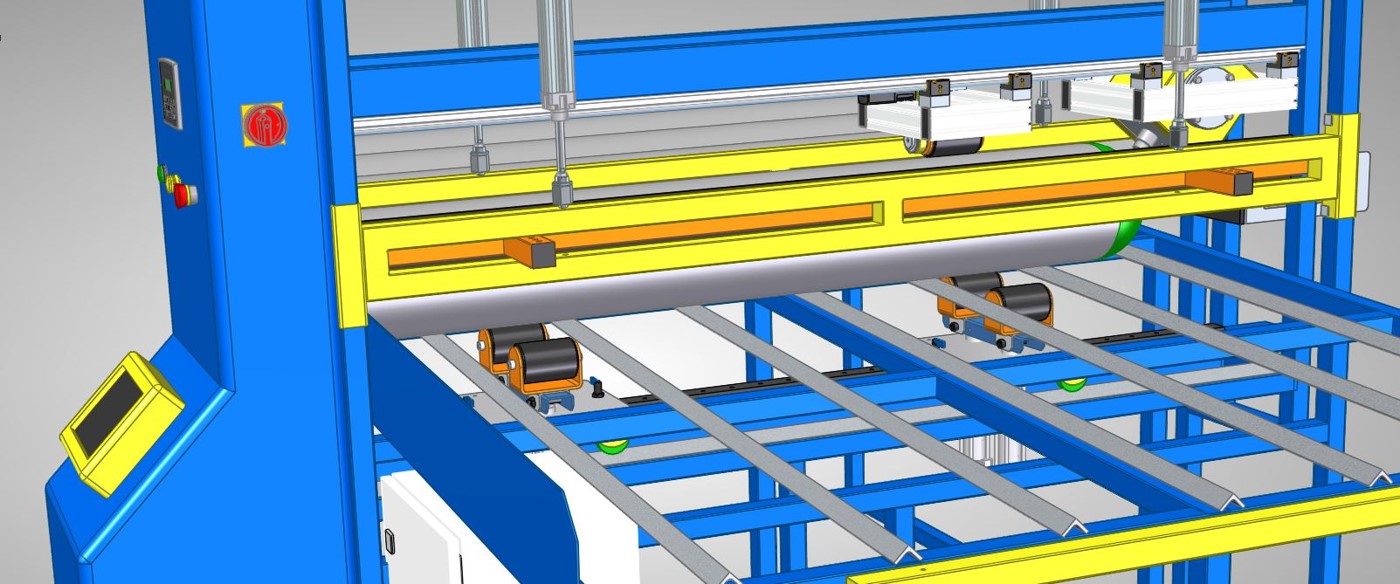

High volume, automatic Gas cylinder marking for production line. High-power, precision dot-marking.Automatic loading and unloading

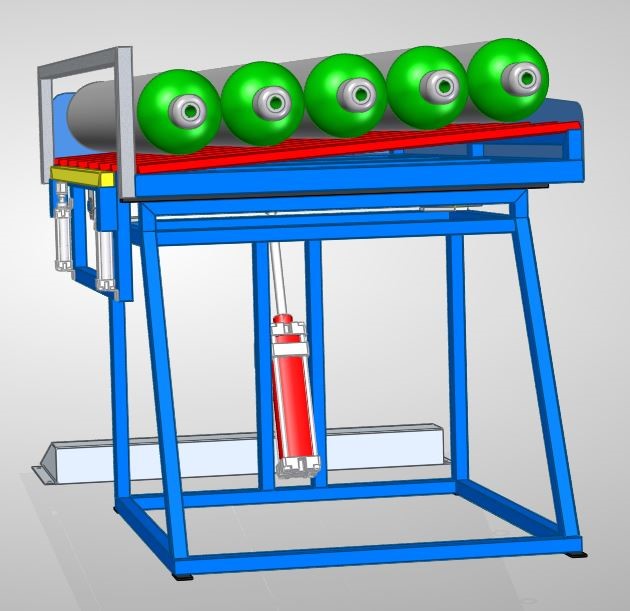

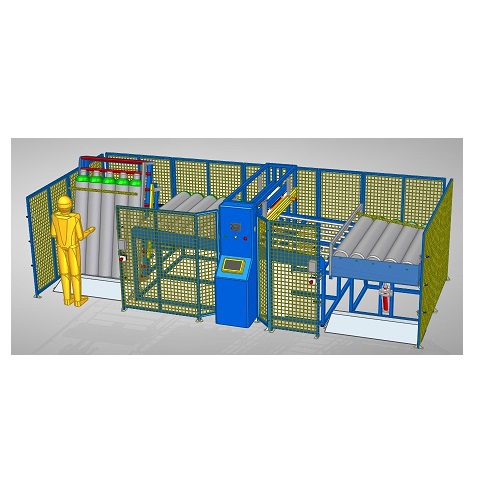

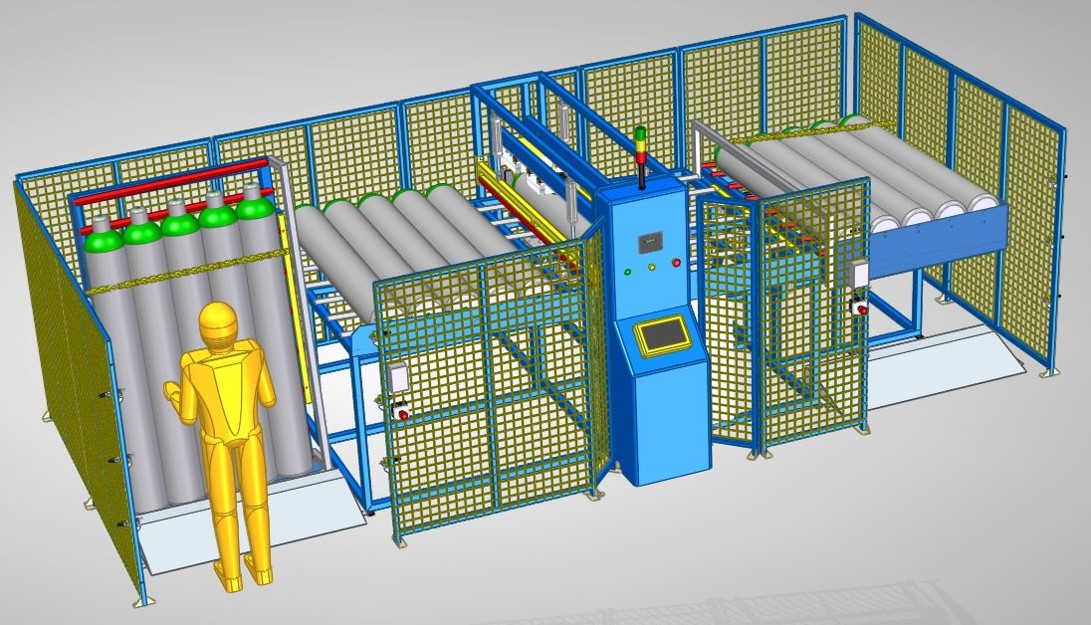

High volume dot marking machine for gas cylinder production line. We offer the machine mainly for high volume production. It is ideal when you have to mark the on same size product, same text – for example gas cylinder production, or new gas cylinder customization. The machine load and unload the gas cylinders in automatic process. It is important that the machine rotating the cylinders during marking. This means we could mark the cylinder all around. We could place a long texts on the gas cylinder hoop or on the gas cylinder neck.

The containt and the parameters of the machining station

- Gas cylinder diameter: 140-280 mm

- Gas cylinder length: 800-1850 mm

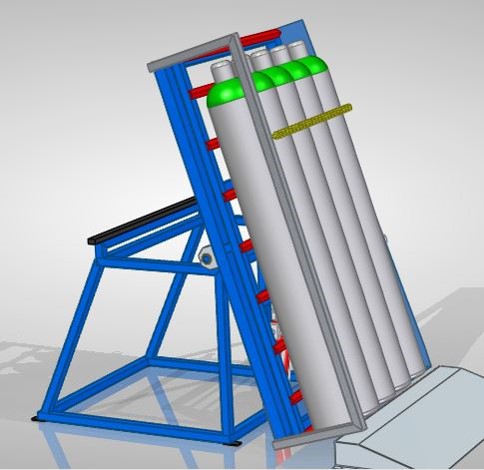

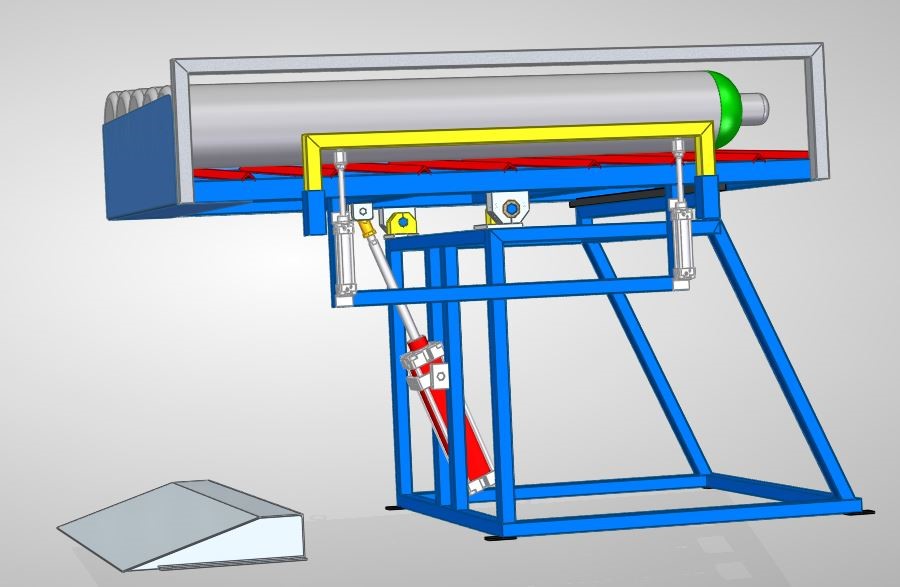

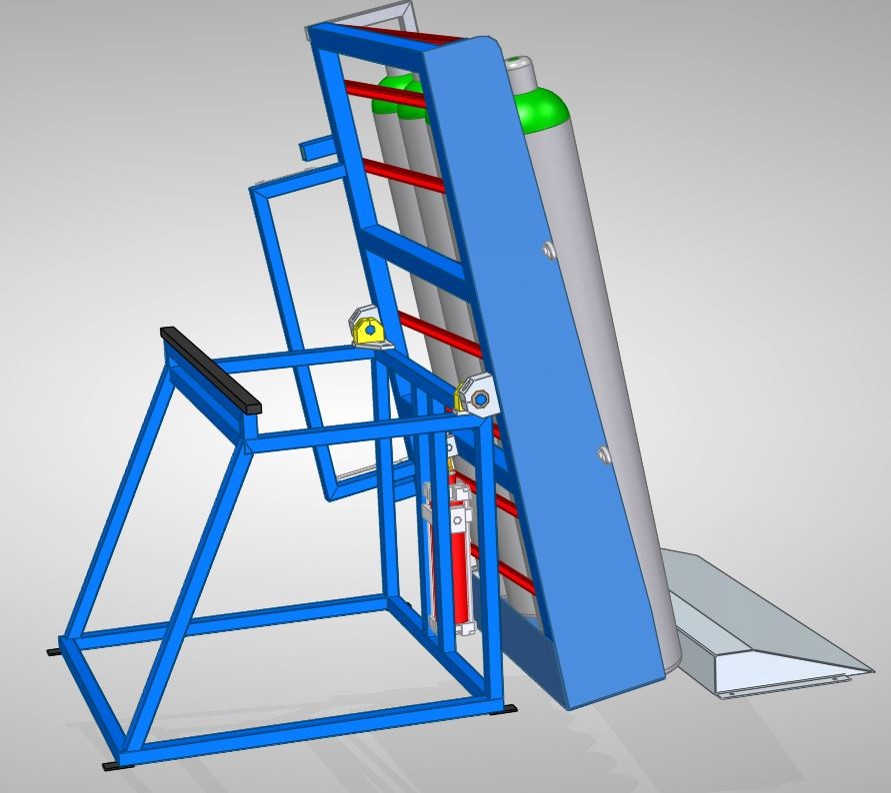

- (option) capacity of the gas cylinder tilting unit:

- 4 pc 280 mm diameter gas cylinder or

- 5 pc 229 mm diameter gas cylinder or

- 8 pc 140 mm diameter gas cylinder

- maximum weight to tilt 350 kg.

- The machine could be work in automat or in manual mode.

- The text could be programmed on touch screen panel with preview. It is similar like in our MK3-X80 machine

The part of the gas cylinder machining station

- pneumatic dot engraving machine

- structure

- controling units

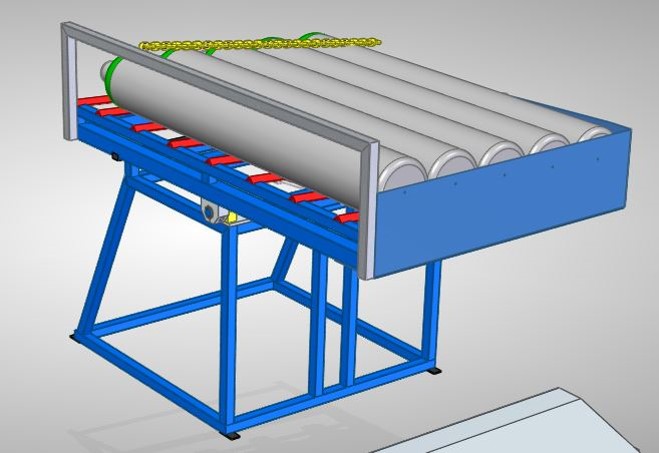

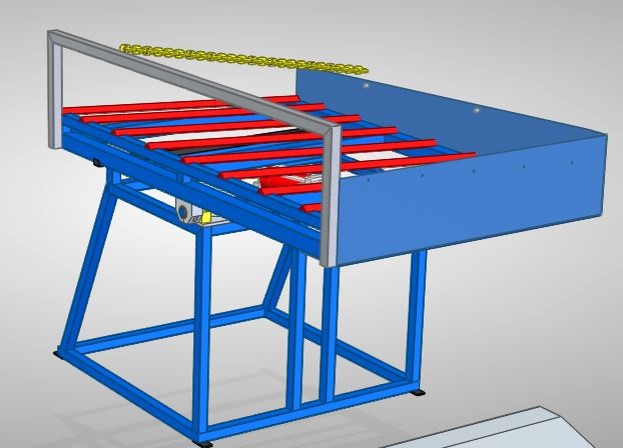

- horizontal track for the gas cylinders before the machine and after the machine

- gas cylinder automatic loading and unloading controls and pneumatic tools (from and to horizontal track)

Optional parts

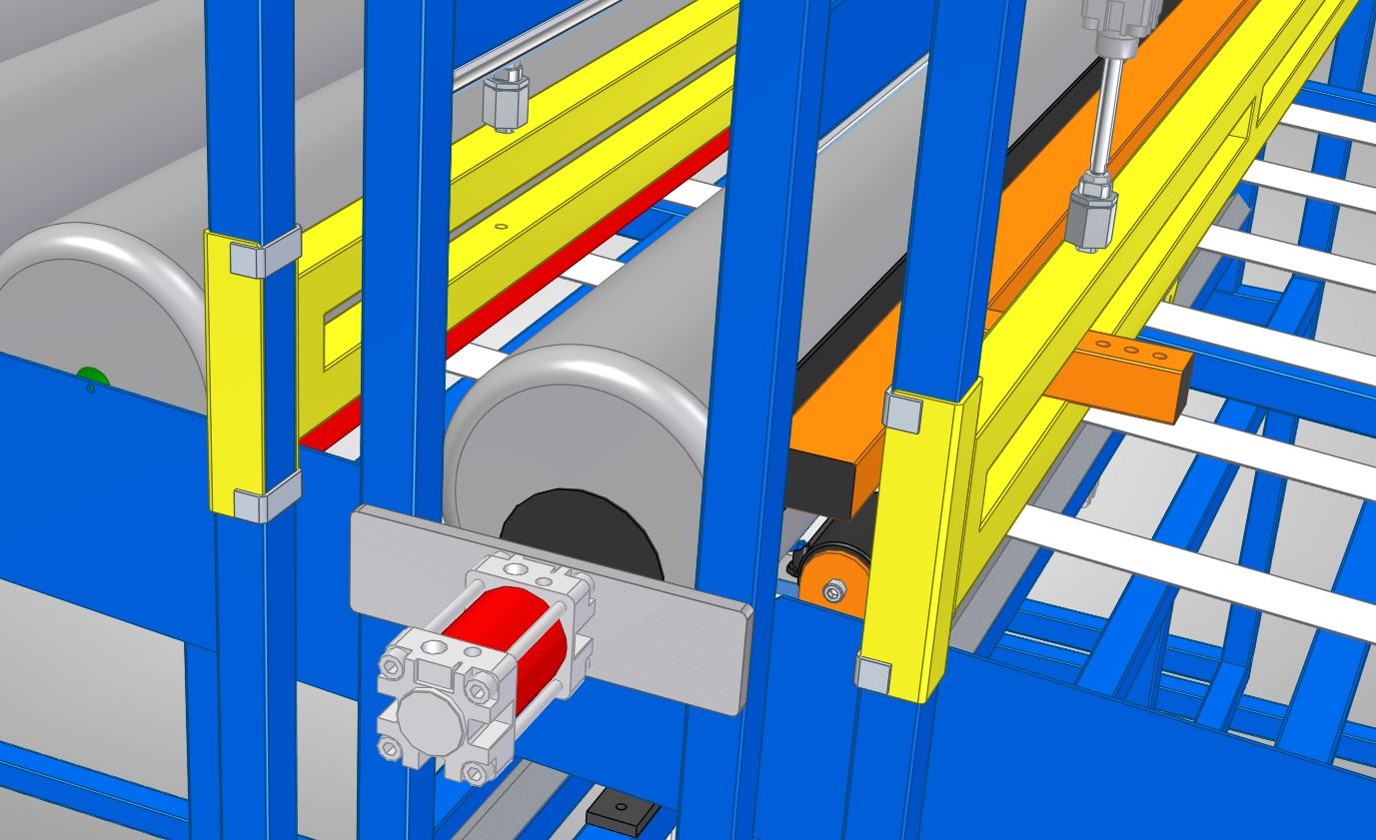

- tilting machine for load and unload of the track

- camera to chack the marking quality and to help the positioning of the marking in manual mode.

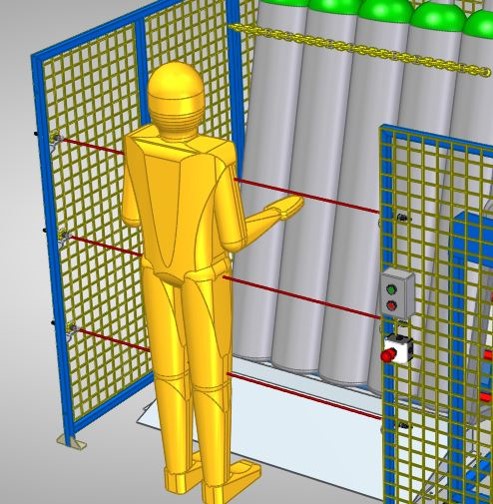

The usage of the marking machine

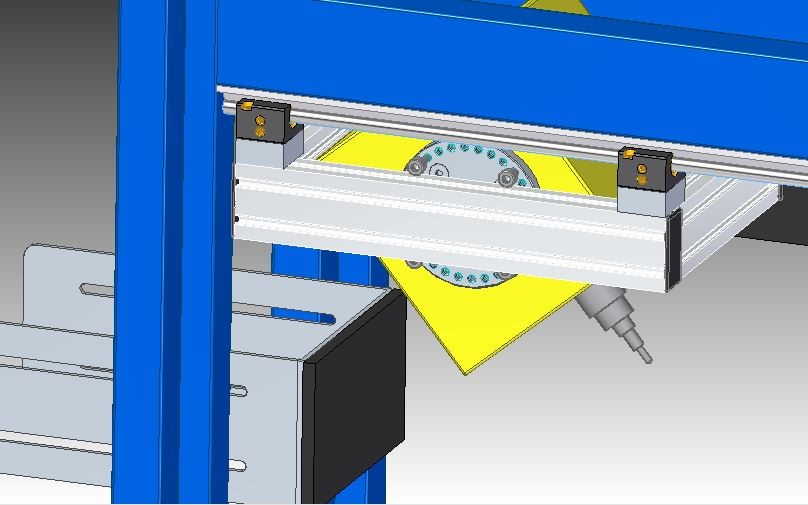

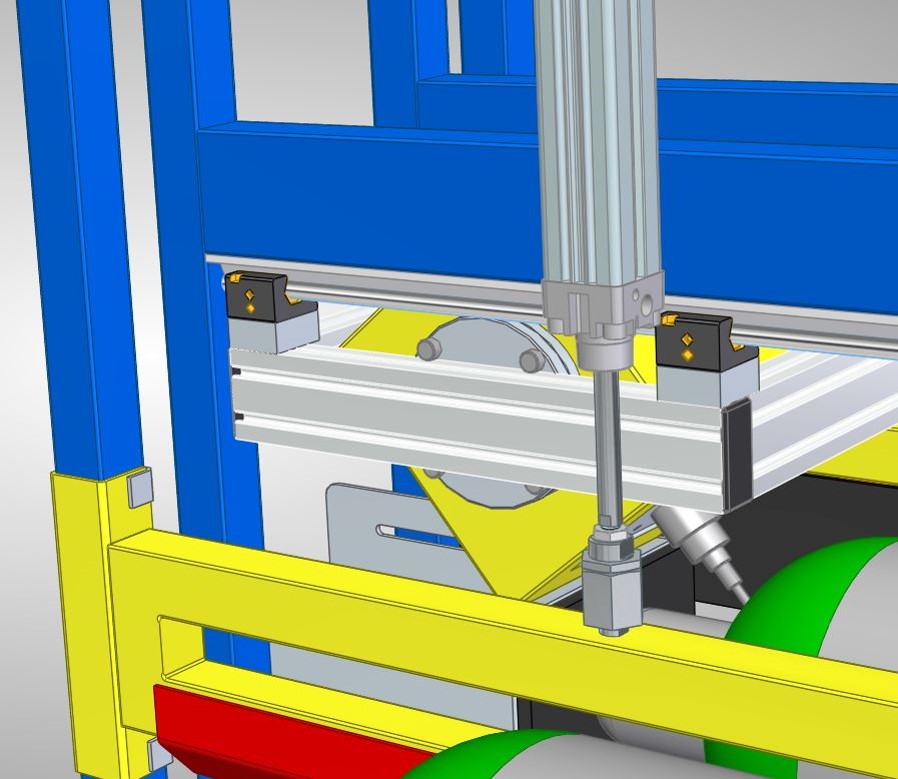

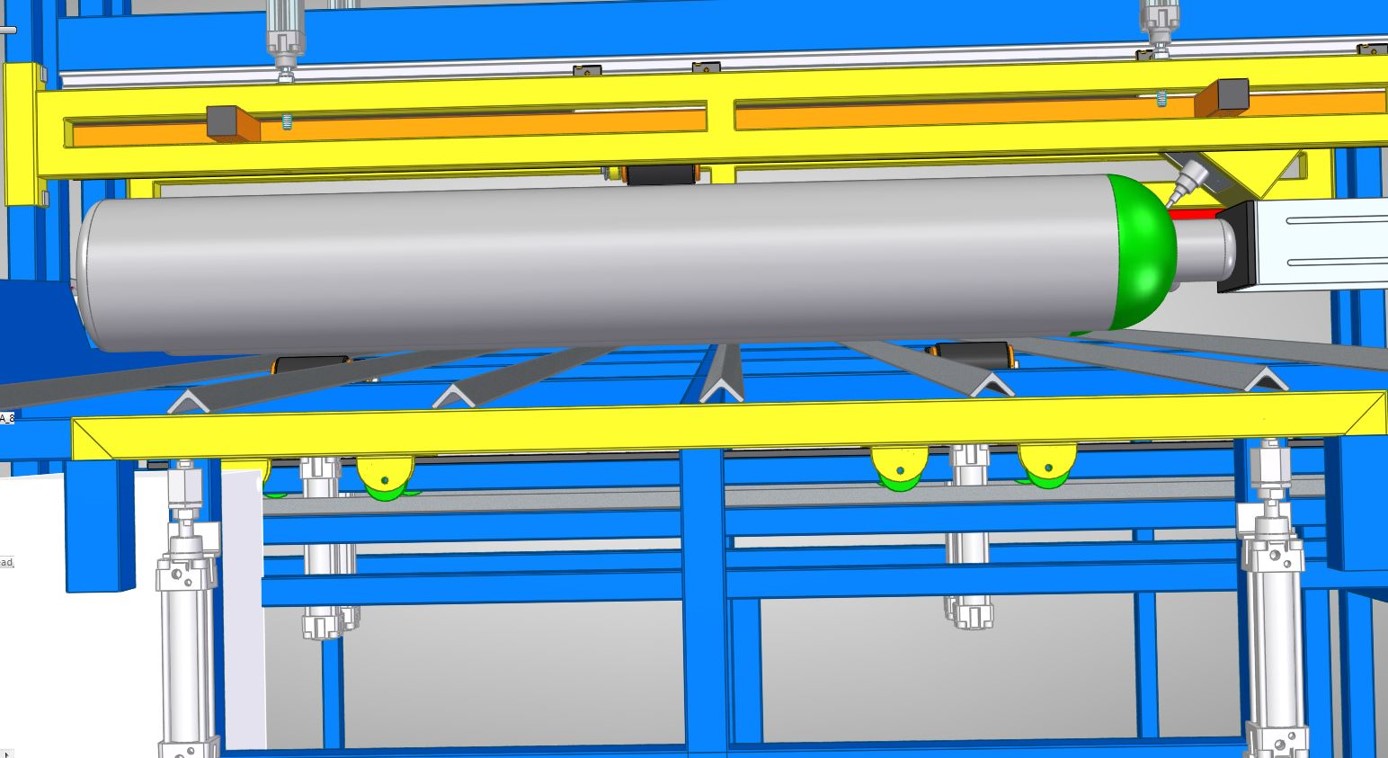

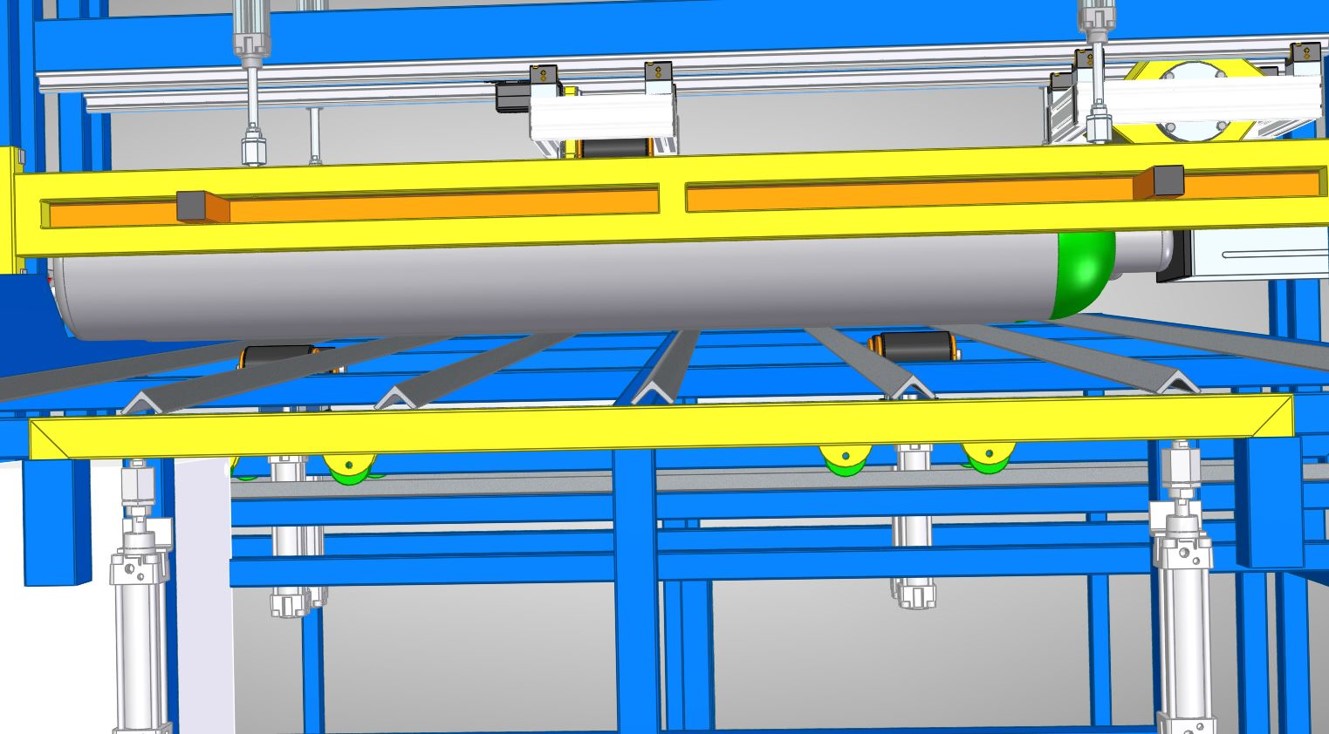

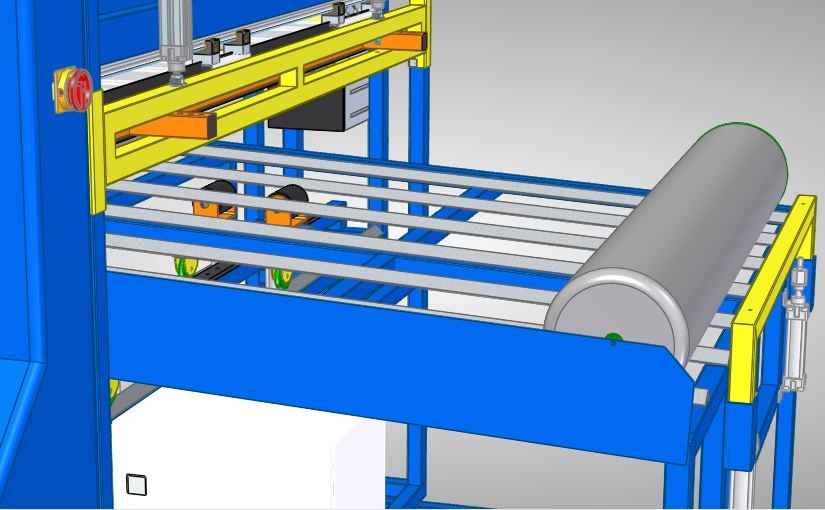

The operator place the gas cylinder to the tilting machine (option). The pneumatic gas cylinder tilting machine – after pushing a button – will turn the cylinders into horizontal postion. Aftewards the gas cylinders will roll to the machining station. Just before the machining station they will knock on the gate of the machinery station. This will just let the gas cylinders one by one into the machining station. In the machining station a pneumatic cylinder will push the cylinder into marking position. In the right position a lifting frame will lift the gas cylinder into dot marking postion.

On the rotating frame there are rollers. We could set the roller distances on this frame. On the rollers the gas cylinder could easily roll. The machine will push the gas cylinder to a controlled roller what is rolled by a stepper engine. The operator set the text to mark on the marking device. After engraving the lifting frame lowered into its original position. On the exit site the gate will be opened. This will unload the gas cylinder from the marking machine. The deflector at the end of the track will stop the gas cylinder. If we mount a tilting machine at the unloading side(option), then the operator could rotate the cylinders into vertical position with button press. .

Unique marks

When you already has a lot of mark on the gas cylinder neck, you should use the manual mode for stamping. On the gas cylinder machining station you could rotate the cylinder manually. With this method you can choose the starting position of the stamping. We have to attach a camera to tha machine (option) to show the cylinder neck to the operator – this is a 7” LCD display.

Set up and installment

The operator has to fulfill several operation before marking. He could fulfill these operations through the service door in service mode. The machine need 6 bar compressed air and 230VAC, 50Hz electrical supply. We install the machine with Fischer adhesive anchor. That is why it is important to have a 100 mm thick smooth concrete basemenet.

Description of the marking

– High-force impact portable marking machine for deep marking, with electro pneumatic percussion for the marking of metals that need to undergo surface treatment like painting and sandblasting.

– Solution for high hardness metals like CrMo54.

– Programmable separate touch-screen control panel, can be connected to a PC

Characteristics of the marking

- Maximum flexibility: high definition, high speed and deep marking

- Indicated for metals, hard metals

Marking

- Marking of variable text, serial numbers, date and time, logos and drawings (DXF and PLT)

- 20 available native fonts, and true type font

- Programmable size, style and direction of text

- DataMatrix code marking according to NASA specifics

Connections

- Serial PC and Ethernet connections

- USB port for importing and exporting complete marking programs

![[:hu]gázpalack jelölése automata gépben[:en]Gas cylinder marking in an automatic machine[:]](https://pwent.eu/wp-content/uploads/2017/01/Gas-cylinder-stamping-complete-automat-machine-2.jpg)

![]Gas cylinder marking in an automatic machine](https://pwent.eu/wp-content/uploads/2017/01/Gas-cylinder-stamping-complete-automat-machine-3.jpg)