QUALITY POLICY

“We at Rama Cylinders are committed to the safety and satisfaction of our customers by understanding their requirements and to supply them with world class quality products through continuous innovation”

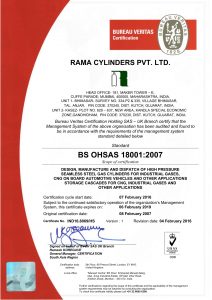

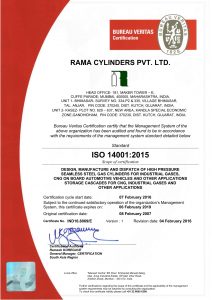

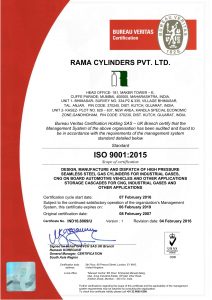

Rama Cylinders is a quality manufacturer of CNG, industrial, fire fighting cylinders and cascades of various capacities. Rama Cylinders is an ISO 9001, ISO 14001 & OHSAS 18001 certified company having two plants in Gujarat. The first is located at Bhimasar-Gandhidham & the second plant is at SEZ-Kandla.

The plants are of world-class standard and have a current installed capacity of manufacturing 480 000 pc/year high pressure seamless steel gas cylinders. The plant is approved by the Bureaou Veritas. The gas cylinders go through on a 100 % hidrostatic pressure testign and 100% ultrasonic inspection as well.

The technology applied to produce the cylinders is hot spinning of seamless steel pipes by Computerized Numerically Controlled (CNC) german machines for closing both ends and subsequently followed by other finishing processes.

The production capability of high pressure seamless steel gas cylinder are:

- 2-240 liter

- 76-406 mm diameter

- up to 400 bar working pressure

- length 400-2200 mm

- standard thread specifications – 25E, 28.8 – DIN 477, 1” BS -341; 25.4 – Type 4 Size 2 – IS:3224; 1” NGT/NPT

- European standard: ISO : 9809-1, ISO : 11439, PED 97/23/EC (CE-Marking), 2010/35/EU TPED (Pi-Marking), ECE-R : 110, EN 1964-1

- Indian standards: IS : 15490, IS : 7285 (Part 1), IS : 7285 (Part 2)

- Other standards: NZS : 5454

RAW MATERIAL

The cylinders are manufactured from Seamless Steel Tubes of superior quality steel, passed through necessary tests and controls having required metallurgical properties made from various grades (i.e. Manganese Steel, Chrome – Moly Steel).

MANUFACTURING PROCESS

The seamless steel cylinders are manufactured by closing bottom & neck forming on CNC hot spinning machine and subjected to all internal tests & controls at every stage of production to assure a quality product w ith cylinders diameters ranging from 76 to 406mm. Accessories such as valve fixing, neck ring, cap and guard are fitted on cylinders as per customer’s requirement. The plant is equipped w ith most modern machineries from reputed Indian & International suppliers to produce superior quality products. The entire production process / testing is controlled by RCPL and done in-house in our own dedicated plant. This ensures tha t RCPL is capable o f offering the right quality cylinder at right price that fits most of the needs of customers.

INSPECTION &TEST

Following inspection and testing activities are carried as per Indian & International standards’ requirements: Dimensional & visual inspection o f raw seamless steel tubes , monitoring of bottom & neck forming temperatures, heat-treatment

parameters monitoring & recording, hardness after heat treatment, mechanical properties – tensile strength, yield strength, % elongation