- For secure high-pressure

- +36 62 999 051

- info@pwent.eu

Products

- Home

- Products

- Products

- Gas cylinder

- CO2 gas cylinder

- Steel 13,4 liter(10 kg CO2) gas cylinder 250 bar test pressure – from NON EU producer

Steel 13,4 liter(10 kg CO2) gas cylinder 250 bar test pressure – from NON EU producer

74,20 €

NON-EU producer 13,4 liter (10 kg CO2). 250 bar test pressure, ~204 mm diameter. Produced according ISO9809-1 EU standard. Steel seamless high pressure gas cylinder from non EU producer. Ready for EU use with all certificate inspection. For minimum order qty and for volumen discounts please contact us

Low cost cylinders from non EU producers mainly from Indian or Chinese producer. The cylinder are approved for european market. Ready to use in EU with all proper certificate and paperwork.

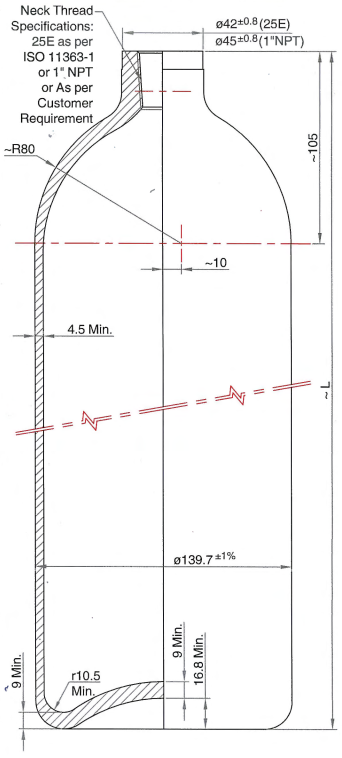

Gas cylinder’s data

- Gas cylinder material: Seamliess steel

- Gas cylinder water capacity: 13,4 liter

- Gas cylinder CO2 capacity: 10 kg CO2

- Gas cylinder test pressure: min, 250 bar

The following data are informative data. It could vary because of different producer.

- Gas cylinder diameter: ~204 mm

- Gas cylinder length: ~585 mm

- Gas cylinder weight: ~18 kg

- Gas cylinder approval: EU norm, ISO9809-1 (we are ready to produce according to different norms)

- Gas cylinder thread: 25E (28,8) or as an option 1” BS -341; 25.4 – Type 4 Size 2 – IS:3224; 1” NGT/NPT;

- Gas cylinder producer: Vary

Steel 13,4 liter (10 kg CO2) gas cylinder with 250 bar test pressure. The gas cylinder could be used for liquified (like carbon dioxide or sulphur dioxide) bundel building or for unique usage. The gas cylinder is available to use liquified cylinder. The gas cylinder fulfills the 2010/35/EU norms and supplied with:

- Declaration of Conformity to the European Directive 2010/35/EU

- Type approval

Steel 13,4 (10 kg CO2) liter gas cylinder 200 bar from Rama Cylinders

Options for gas cylinder

- Gas cylinder valves

- Gas cylinder cap

- Gas cylinder cage from plastic or steel

Please contact us, because we are glad to be at your service in case…

- you cannot find the gas cylinder type what you are looking for

- you are not certain about some technical details what is imortant for you

- if you cannot choose between the gas cylinders and product

- if you have some problem for what you cannot find an answer

The plant is approved by the Bureaou Veritas. The gas cylinders go through on a 100 % hidrostatic pressure testign and 100% ultrasonic inspection as well.

The technology applied to produce the cylinders is hot spinning of seamless steel pipes by Computerized Numerically Controlled (CNC) german machines for closing both ends and subsequently followed by other finishing processes.

The production capability of high pressure seamless steel gas cylinder are:

- 2-240 liter

- 76-406 mm diameter

- up to 400 bar working pressure

- length 400-2200 mm

- standard thread specifications – 25E, 28.8 – DIN 477, 1” BS -341; 25.4 – Type 4 Size 2 – IS:3224; 1” NGT/NPT

- European standard: ISO : 9809-1, ISO : 11439, PED 97/23/EC (CE-Marking), 2010/35/EU TPED (Pi-Marking), ECE-R : 110, EN 1964-1

- Indian standards: IS : 15490, IS : 7285 (Part 1), IS : 7285 (Part 2)

- Other standards: NZS : 5454

RAW MATERIAL

The cylinders are manufactured from Seamless Steel Tubes of superior quality steel, passed through necessary tests and controls having required metallurgical properties made from various grades (i.e. Manganese Steel, Chrome – Moly Steel).

MANUFACTURING PROCESS

The seamless steel cylinders are manufactured by closing bottom & neck forming on CNC hot spinning machine and subjected to all internal tests & controls at every stage of production to assure a quality product w ith cylinders diameters ranging from 76 to 406mm. Accessories such as valve fixing, neck ring, cap and guard are fitted on cylinders as per customer’s requirement. The plant is equipped w ith most modern machineries from reputed Indian & International suppliers to produce superior quality products. The entire production process / testing is controlled by RCPL and done in-house in our own dedicated plant. This ensures tha t RCPL is capable o f offering the right quality cylinder at right price that fits most of the needs of customers.

INSPECTION &TEST

Following inspection and testing activities are carried as per Indian & International standards’ requirements: Dimensional & visual inspection o f raw seamless steel tubes , monitoring of bottom & neck forming temperatures, heat-treatment

parameters monitoring & recording, hardness after heat treatment, mechanical properties – tensile strength, yield strength, % elongation

| Weight | 50 kg |

|---|---|

| Dimensions | 22,9 × 150 cm |

Related products

- Ajánlatkérés

Acél 67,5 liter (50kg CO2) liter gázpalack 200 bar

67,5 liter (50 kg CO2) / 200 bar üzemi nyomás/ 267 mm átmérő / 1500 mm hossz/ 74 kg súly/ ISO9809-1 Európai szabvány szerint

Acél magasnyomású gázpalack amelyet a Rama Cylinders gyártott.

Minimális rendelési mennyiségért és mennyiségi kedvezményért keressen bennünket

- Ajánlatkérés

Acél 50 liter gázpalack 200 bar

168,00 €50 liter/ 200 bar üzemi nyomás/ 229 mm átmérő / 1500 mm hossz/ 54 kg súly/ ISO9809-1 Európai szabvány szerint

Acél magasnyomású gázpalack amelyet a Rama Cylinders gyártott.

Minimális rendelési mennyiségért és mennyiségi kedvezményért keressen bennünket

- Ajánlatkérés

Acél 3 liter (2kg CO2) liter gázpalack 200 bar

37,80 €3 liter (2 kg CO2) / 200 bar üzemi nyomás/ ISO9809-1 Európai szabvány szerint

Acél magasnyomású gázpalack amelyet a Rama Cylinders gyártott.

Minimális rendelési mennyiségért és mennyiségi kedvezményért keressen bennünket

- Ajánlatkérés

Acél 50 liter gázpalack tengerálló festés, 200 bar, európai gyártó

232,00 €Acél gázpalack 50 liter tengerálló festéssel. 200 bar üzemi nyomás, európai gyártó. Mennyiségi kedvezményért keressen bennünket

![[:hu]Acél 50 liter gázpalack tengerálló festés[:en]Steel 50 liter gas cylinder seaproof paint, 200 bar[:]](https://pwent.eu/wp-content/uploads/2016/11/seaproof-gascylinder-300x300.png)