- For secure high-pressure

- +36 62 999 051

- info@pwent.eu

Pressure test pump

Showing all 6 results

- Ajánlatkérés

N7/1FH-E-portable electric testing pump for extinguishers

1 860,00 €The pump is easily transportable as it is installed on a trolley equipped with a special three-wheeled structure.

- Ajánlatkérés

N7/1FH-EAA-portable electric testing pump for extinguishers

2 820,00 €Easily adaptable to different testing needs, this flexible pump does not need any compressed air for its functioning

- Ajánlatkérés

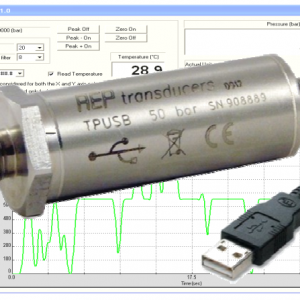

Pressure transmitter TPUSB.432.R0

Pressure transmitter TPUSB.432.R0 with USB connection from 100 mbar to 2000 bar, and with free software.

- Ajánlatkérés

Pressure data logger (100mbar-3000 bar on your request)

Pressure data logger digital. Pressure ranges 0-160 bar, 0-600 bar or 100mbar – 3000 bar on your request.

Pressure test pumps are indispensable in various industries, particularly in construction and manufacturing, where they play a crucial role in testing the integrity and leak resistance of systems such as pipelines and pressure vessels. These pumps are not directly responsible for detecting leaks but are essential for applying the necessary pressure to a system to facilitate leak testing.

The Functionality of Pressure Test Pumps

These pumps operate by injecting a liquid, usually water, under high pressure into a system to test its robustness. They are crucial in preparing a system for leak detection, as a steady pressure reading can help professionals identify a well-sealed system, whereas a drop in pressure may indicate the presence of a leak. Available in manual, electric, and pneumatic types, pressure test pumps cater to different operational needs and budgets, and they are suitable for both low-pressure and high-pressure applications.

Advantages of Pressure Test Pumps

The primary advantage of pressure test pumps lies in their ability to efficiently pressurize a system, which is essential in preparing for leak detection processes. Their design allows for quick system pressurization, which is particularly beneficial in large-scale industrial settings where time efficiency is crucial. It’s important to note that while these pumps facilitate the testing process, the actual detection of leaks is typically carried out through other means, such as pressure gauges or specialized sensors.

These pumps’ design also allows for fast filling of the system and rapid pressurization. This feature is particularly beneficial in large-scale industrial applications where time is a critical factor. The ability to quickly fill and pressurize a system contributes to a more efficient and effective testing process.

Role in Industrial Applications

Pressure test pumps play a vital role in maintaining system integrity and safety. Different types of pumps serve specific purposes:

Manual Pressure Test Pumps: These are often used in smaller applications or in environments where electricity is not readily available. Manual pumps are ideal for low-pressure systems and are commonly used in plumbing, heating, and small pipeline systems for routine maintenance and testing.

Electric Pressure Test Pumps: Electric pumps are suited for applications requiring consistent and continuous pressure application. They are commonly employed in large-scale industrial settings, such as in chemical plants, power stations, and large pipeline systems, where their ability to quickly and efficiently pressurize a system is crucial.

Pneumatic Pressure Test Pumps: These pumps are used where there’s a need for high-pressure output with precise control, often in environments where explosive gases are present and electrical pumps may pose a risk. Pneumatic pumps are prevalent in the oil and gas industry, particularly in offshore settings, for testing pipelines and valves under extreme conditions.

High-Pressure Test Pumps: Designed for systems that operate under very high pressure, these pumps are crucial in industries like aerospace and automotive manufacturing. They are used to ensure the integrity of high-pressure systems like hydraulic lines and fuel systems, where even a small leak can have significant consequences.

Low-Pressure Test Pumps: Typically used in residential and light commercial applications, low-pressure pumps are essential for testing water lines, heating systems, and air conditioning units. They help ensure these systems are leak-free and operating efficiently, which is crucial for safety and energy conservation.

Each type serves a unique role, catering to the varied demands of different industrial sectors. Their contribution to ensuring the reliability, safety, and efficiency of pressure systems is invaluable, making them a cornerstone in the maintenance and operation of a wide range of industrial applications.

Pwent delivers advanced pressure test pumps, designed for exceptional accuracy and efficiency in leak detection, enhancing safety and reliability in industrial applications.