- For secure high-pressure

- +36 62 999 051

- info@pwent.eu

Valve mounting

Showing 1–12 of 20 results

- Ajánlatkérés

74W14-300 Torque Wrench

Durable construction, 100,000 tightening accuracy guaranteed

- Ajánlatkérés

Bahco 7465 Torque Wrench

• Solid metal, durable design.

- Ajánlatkérés

Bahco TAW14340 Torque Wrench

Up to 50 tightening values can be stored in its own memory.

- Ajánlatkérés

Holex 657277 Torque Wrench

Torque wrench tested according to DIN EN ISO 6789.

- Ajánlatkérés

Norbar Clicktronic 340 Torque wrench

Supplied with built-in rechargeable lithium battery and charging cable.

- Ajánlatkérés

EL60 – Electric valving/ devalving unit

Electrical valve mounting and demounting unit in more design 80-400 Nm

- Ajánlatkérés

EL100-C – Electric valving unit for small cylinder with parallel threads

El100-C Electric Valving for a parallel thread small cylinder. Mainly used for powder fire extinguisher with parallel thread valving/ devalving operation. Cylinhder diameter 50-240 mm

- Ajánlatkérés

EL60-E – Electric valving unit for small cylinder

El-60-e Electric Valving for a small cylander

- Ajánlatkérés

EL60-ATEX – Electric valving/ devalving unit

14 400,00 €EL60 ATEX- Electric valving can be used in environments where explosive gases are found .

- Ajánlatkérés

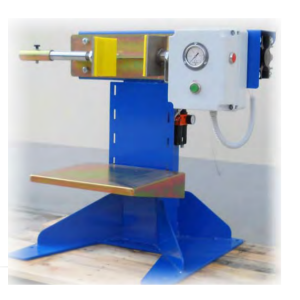

Air5- pneumatic vice

2 650,00 €High strength pneumatic vice for gascylinders and fire extinguisher safe maintenance. More version (with support, high stength or low strength…)

- Ajánlatkérés

Air5B- horizontal pneumatic vice

1 740,00 €High strenght pneumatic vice for gascylinder and fire extinguisher safe maintenance. More design (with stand support, high strength, low strength…)

- Ajánlatkérés

Air4-Pneumatic vices

1 850,00 €AIR series vices ensure a perfect clamping of cylinders and extinguishers. The whole range of maintenance operations such as punching, valve assembling and dismantling including powder extinguishers pressurization are easily achievable.

Valve mounting is an essential procedure in the gas storage and handling sector, playing a crucial role in the safety and efficiency of gas storage systems. This process involves precisely installing valves on gas storage tanks or cylinders, a critical step in managing the controlled flow of gas in and out of these containers. Understanding the intricacies of this is vital for maintaining the integrity and functionality of gas storage systems.

Importance of Valve Mounting

The significance of it in the gas storage industry cannot be overstated. Proper valve mounting is essential for safe gas storage operations. It involves not only preventing gas leaks and maintaining appropriate pressure levels but also ensuring the compatibility of valve types with specific gases to avoid hazardous mixtures. The torque applied during valve installation is of paramount importance; different cylinder sizes and valve materials require specific retraction torques according to standards. Incorrect torque can lead to thread and cylinder damage, potentially compromising the entire system’s safety.

Valve Mounting Tools and Techniques

Pwent provides a range of manual wrenches and machines tailored for valve mounting, designed to deliver precise torque and reduce the risk of errors. For applications with lower torque requirements, such as in fire extinguishers, our tools ensure accurate force application typically below 100 Nm. This precision is crucial in avoiding damage to both the valve and the cylinder. Improper handling or faulty actuation during valve mounting can not only damage the valve but may also render the cylinder unusable.

Addressing Residual Pressure and Safety Concerns

The management of residual pressure during valve installation is a critical safety aspect. If not properly controlled, residual pressure can lead to personal injury. Our tools and procedures are designed to safely handle these pressures, ensuring that valve mounting is conducted in the safest manner possible.

This is a pivotal process in the gas storage industry, with its importance resonating through every aspect of gas storage and safety. The use of specialized manual wrenches and machines for this plays a significant role in ensuring this process is carried out with the utmost precision and care. Our company’s commitment to providing high precisity torque with safety barriers to avoid injuries for this reflects our dedication to supporting the safety and efficiency of gas storage facilities.

Choose Pwent valve mounting for unmatched precision and reliability in gas storage, ensuring your systems operate safely and efficiently.