In our product range you could find many type of pressure testing machine. That is why it is rather easy to be confused. To avoid your confusion and save your money we help you to choose the best pressure testing machine for your industrial high pressure cylinders for for your fire extinguishers. It is important for us to suit you machine for hydrostatic testing on the following fields:

- fire extinguisher hydrostatic testing

- low pressure gas cylinder inspection

- high pressure gas cylinder testing

You could find the hydrotest procedure for tanks as well in this article.

It is not easy to choose the suitable pressure testing machine, what is suit to your needs

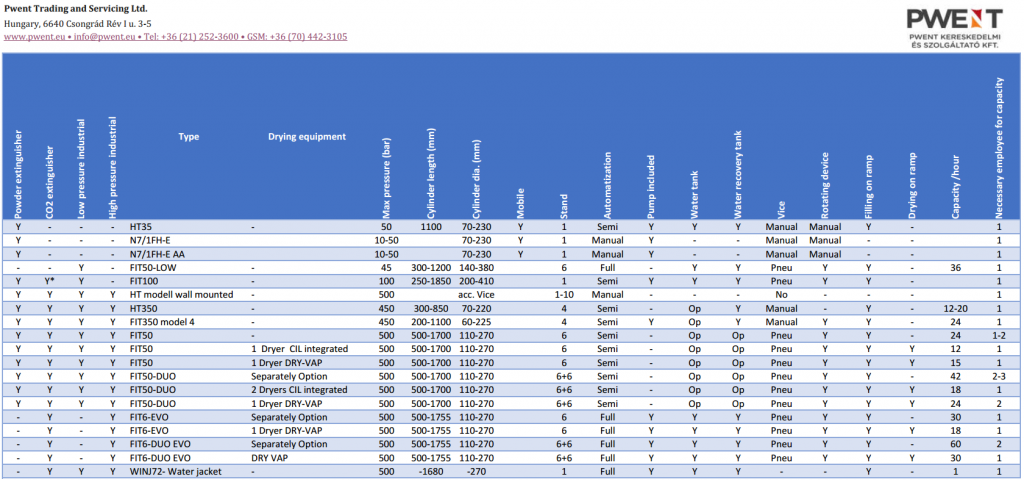

Regularly we test the cylinders on half times hiren pressure than the normal working pressure. A 200 bar cylinder is tested on 300 bar. We do the pressure testing with water. The water is just very slightly compressable. That is why if the tank cannot stand the pressure there won’t be explosion. The worst case there will be just some water around. Our pressure testing machine help the pressure testing processes in different level of automatization. The table above contains all proper data about our solutions. It give you keypoint for your choice. The table contains pressure, gas cylinder dimension, and hourly expected capacity as well.

Powder fire extinguihser testing

You regularly pressurized the powder fire extinguishers with 10-15 bar. That is why we test the tanks with less than 50 bar. Mainly we offer manual solutions for this area, ready to do the job on site. Our mobile range are the following:

- HT35

- N7/1FH-E

- N7/1FH-E AA (it include a blower to dry inside the fire hose)

CO2 fire extinguisher pressure testing

CO2 means higher pressure than the powder extinguishers. The CO2 has a liquide and gas phase within the gas cylinder. The gas phase above of the the liquide state is keep the same pressure permananent (~67,5 bar). It is just change very little according to the temperature. The CO2 cylinders regularly used for Carbon dioxide fire extinguishers are with 250 bar or maybe 212 bar test pressure.

Low pressure and high-pressure industrial cylinders

For low pressure industrial gas cylinders we offer the FIT50-LOW pressure testing machine. The pressure testing machine is optimized for cylinder with welded cage. A special attachment is designed what make possible a complete automatic cycle for filling/testing/emptying of the cylinder. If you mainly work with high pressure cylinders and just a few low pressure, then you could use the FIT50 as well, but because of the welded cage and the big diameter you will have many extra labour hour.

FIT SERIES – pressure testing machine

We produce the testing benches FIT series in 4 main versions, each version with some options as follows:

Versions of FIT pressure testing machine

- FIT50: this is a Semi-Automatic test bench. It allows testing 6 cylinders each cycle.

- FIT50-DUO: this is a Semi-Automatic test bench. It allows testing 6+6 cylinders each cycle.

- FIT-6-EVO: this is an Automatic test bench. It allows testing 6 cylinders each cycle.

- FIT-6 DUO-EVO: this is an Automatic test bench. It allows testing 6+6 cylinders each cycle.

WORKING PRINCIPLES. hydrotest procedure for tanks

FIT50

This equipment allows filling the cylinders with water, testing them with water and finally emptying them from water. We can recover or purge the used water according to the customer’s applied testing procedure. The operator has to manually fit the filling heads, the testing heads and the emptying heads on the cylinders before each step.

- TIMING: to load the bench with 6 cylinders of 50 litres, to test them at 300 bar, to empty them and to unload them from the bench it takes approx. 12-15 minutes. Therefore, you can test approx. 24 cylinders/hour.

- DRYING: after the testing operations, the cylinders must be dried. The suggested drying equipment are: CIL model or DRY-VAP model.