Gázpalack tárolás és szállítás

Gázpalack köteg

Gázpalack fém paletta

Gázpalack szállító láda

Gázpalack trailer

Tűzoltókészülék karbantartási gépek

Portöltők

CO2 töltők

Mobil műhely

Kémiai oltóanyagokhoz gépek

Inert gáztöltés (Argon, Nitrogén)

Gázpalack karbantartó gépek

Szelepelés

Nyomáspróba

Pumpa

Szárítás

Tisztítás

Állandó jelölés

Lézerjelölés

Présjelölés

DOT-PEEN pontgravírozás

Görgetéses jelölés

Karcjelölés

Hőjelölés

Tudásbázis

A Pwent Kft gázpalackok gázpalack kötegek, rendszerek és a hozzájuk kötődő karbantartó gépekre specializálódott. Gázpalack és tűzoltó készülék karbantartó gépeink között megtalálható a nyomáspróbázó berendezés, szelepelő gép, oporral töltő és visszanyerő berendezés, széndioxid pumpa és sok minden más. Kérem böngéssze át termékeinket vagy vegye fel velünk a kapcsolatot.

- Ajánlatkérés

EXT-PRESS porraloltó nyomás alá helyező készlet

282,00 €Porral oltók nitrogénnel történő rátöltéséhez. Nyomáscsökkentővel, flexibilis csővel de gázpalack nélkül

- Ajánlatkérés

PWENT gázpalack köteg (Álló) 16 x 50 liter

PWENT 16 x 50 liter gázpalack köteg 200 bar, 300 bar vagy 350 bar üzemi nyomással, permanens vagy cseppfolyósítható gázokhoz. A gázpalack kötegeink az EU szabványoknak megfelelően kerülnek legyártásra. Hegesztett galvanizált szerkezet rozsdamentes kialakítású gyűjtőcsövezéssel, s sok más egyéb előnnyel. Kérem kattintson a részletekért. Egyedi tervekért és kivitelezésért illetve mennyiségi kedvezményekért kérem hívjon

- Ajánlatkérés

QUICK-PRESS gyorscsatlakozó porraloltók nitrogénnel történő rátöltéséhez

520,00 €A csatlakozóval gyorsan rácsatlakozhatunk ¼” BSP anya menettel rendelkező porral-oltóra. A szükséges nitrogén rátöltés és nyomás alá helyezés gyorsan megtörténhet. Növeli a termékenységet.

- Ajánlatkérés

“B” típus – Legvédettebb acél gázpalack trailer

95000,00 €Típus “B” – Legvédetteb acél gázpalack trailer, amely megnehezíti a rongálást és visszaélést. A nehezebb zárható acélszerkezet megfelelő biztonságot nyújt veszélyesebb országokban vagy magasabb biztonsági követlemények mellett. Az itt kiajánlott ár gázpalack nélkül értendő.

- Ajánlatkérés

GBM MIX/P16

32000,00 €Gázpalack kötegekbe töltött gázok keverése. Gázok homogenizálása. A keverő lehetővé teszi a komplett gázpalack köteg megfordítását és keverőprogramjával felgyorsítja a gázkeverékek homogenizálását vagy az oltógázok (FM200, NOVEC1230…) nitrogénnel történő keveredését, diffúzióját

- Ajánlatkérés

Menetvágó 25E (28,8×1/14”) gázpalack kúpos menet vágásához, felújításához

Menetvágó 25E (28,8×1/14”) gázpalack nagy kúpos menet vágásához, tisztításához, felújításához

- Opciók választása

SKID AC/FG8 Mobil CO2- és portöltő berendezés tűzoltókészülékek karbantartásához

10900,00 € – 11980,00 €SKID AC/FG8 egy hordozható egység, amely minden fontos elemet tartalmaz ahhoz hogy a szénidoxid- és a porral-oltó készülékek szervizét a helyszínen el lehessen végezni.

- Tovább olvasom

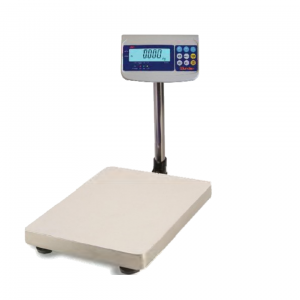

ETW elektronikus mérlegek töltéshez ellenőrzéshez

850,00 € – 1260,00 €Az ETW sorozattal pontosan megmérheti és ellenőrizheti az oltókészülék súlyát töltés közben. maximális súly 100-300 kg, 10/20 grammos osztással

- Ajánlatkérés

FIT 6-DUO EVO csúcskategóriás automata próbapad 6+6 gázpalack részére

130000,00 €A Fit-6-EVO-DUO teljes automata próbapad 6+6 palackhoz. Csak 25E menethez. Feltöltés, nyomáspróba, leürítés, egyetlen csatlakozón keresztül történik. Maximális nyomásérték: 450 bar.Gázpalack átmérő: 110-270 mm Gázpalack hossz: 500-1755 mm Kapacitás maximum: 30 palack/óra.

- Ajánlatkérés

Kaliber 17E (19,8×1/14”) gázpalack kúpos menet vizsgálatához

Dugós és menetes kaliber 17E (19,8×1/14”) gázpalack nagy kúpos menet vizsgálatához

- Ajánlatkérés

PWENT gázpalack köteg (Álló) 12 x 50 liter

PWENT 12 x 50 liter gázpalack köteg 200 bar, 300 bar vagy 350 bar üzemi nyomással, permanens vagy cseppfolyósítható gázokhoz. A gázpalack kötegeink az EU szabványoknak megfelelően kerülnek legyártásra. Hegesztett galvanizált szerkezet rozsdamentes kialakítású gyűjtőcsövezéssel, s sok más egyéb előnnyel. Kérem kattintson a részletekért. Egyedi tervekért és kivitelezésért illetve mennyiségi kedvezményekért kérem hívjon

- Ajánlatkérés

Gyűrűs kaliber 25E (28,8×1/14”) gázpalack szelep kúpos menet vizsgálatához

Gyűrős kaliber 25E (28,8×1/14”) gázpalack szelep nagy kúpos menet vizsgálatához